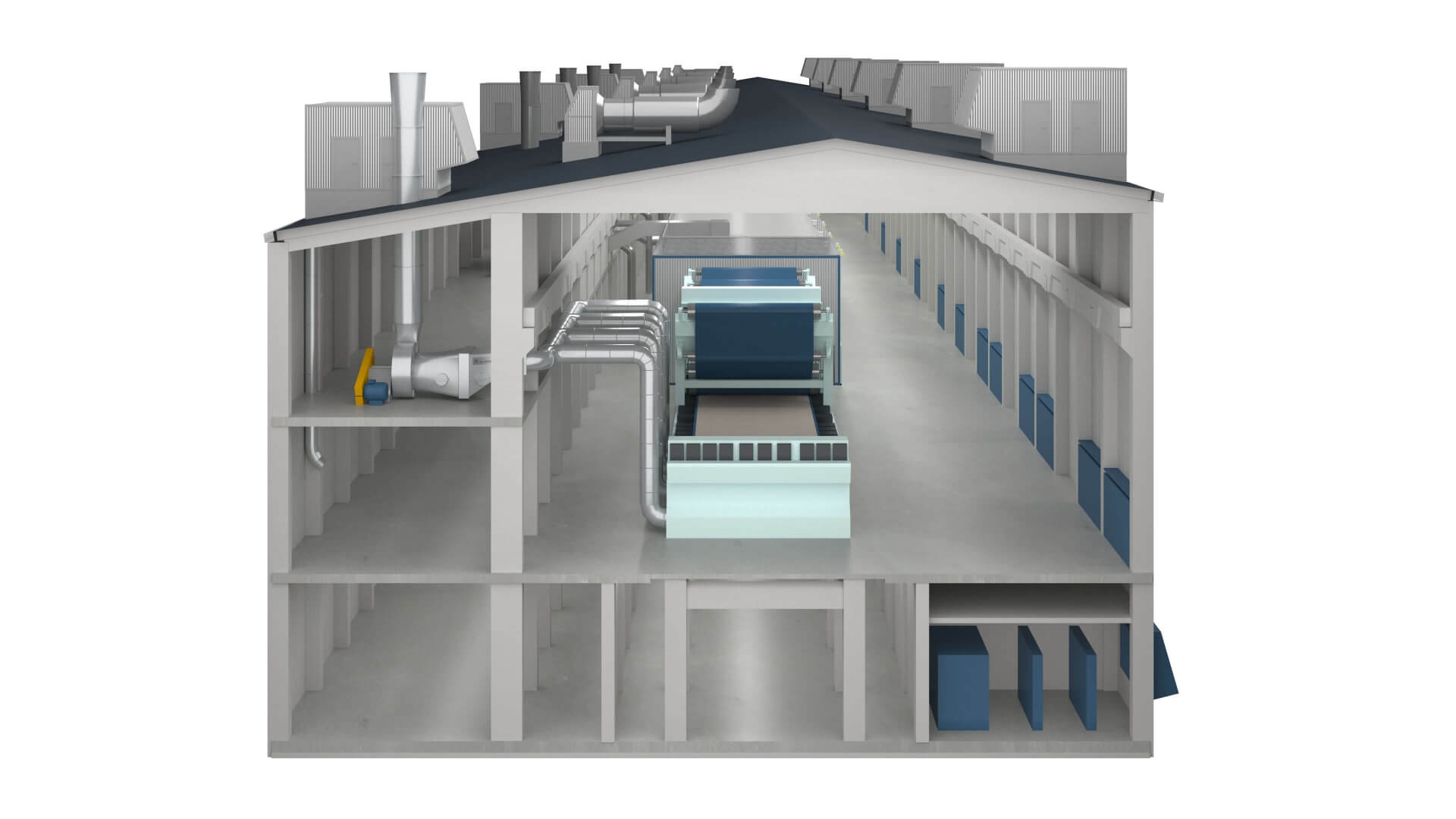

HVAC SYSTEMS TO IMPROVE INDOOR AIR AND MAXIMIZE ENERGY EFFICIENCY

TM Systems offers complete HVAC systems and machine hall ventilation systems including supply air units, exhaust air units, mancoolers, ceiling ventilation and supply of heating energy. Special care is taken to minimize the noise emissions.

MACHINE HALL VENTILATION – PROTECT PEOPLE AND FACILITIES

Low machine hall temperatures combined with high humidity often cause condensation and deterioration of the building and machinery. On the other hand, excessively high temperatures can decrease the alertness of machine operators.

Our solutions are helping our customers in various industries to improve the indoor air with highest efficiency.

KEY BENEFITS

- Optimized design allows accessibility and easy maintenance.

- Fresh air is supplied into the machine hall in an optimized way.

- Good working conditions are maintained for personnel and mill machinery.

- The machine hall building and machinery are protected from deterioration and corrosion.

- The energy usage needed for building heating is minimized.

- Wet end ventilation reduces water vapor and heat emissions into the machine hall.

HOW CAN I BENEFIT?

MACHINE HALL VENTILATION PROJECTS

Delivery of heat recovery tower and machine hall ventilation system for a customer in the Finnish packaging industry.

TM Systems successfully completes a large project delivery: hood, air system, wet-end process ventilation, runnability components, heat recovery, and hall ventilation delivered to the world’s leading pulp and paper manufacturer.

Ventilation of the machine hall for a forestry company in China.

HVAC SYSTEMS FOR IMPROVED ENVIRONMENT

TM Systems offers HVAC equipment for machine halls, turbine halls, boiler rooms, control rooms, electrical rooms, laboratories, and special rooms. We provide turnkey solutions, including engineering, delivery, and installation of the equipment.

Our HVAC projects have enhanced our customers’ facilities and provided social benefits through fresh air and long-lasting products.

Contact us for more information!

HVAC – HEALTHY, SUSTAINABLE AND SAFE ENVIRONMENT FOR PEOPLE AND MACHINERY

WHY HVAC?

- Optimizing the supply of fresh air minimizes energy usage.

- Reducing production downtime.

- Controlled air temperature and humidity help avoid condensation, deterioration, and corrosion of the building, machinery, and electrical devices, thus increasing their lifetime.

- Providing ideal working conditions for personnel.

LATEST HVAC DELIVERIES

A major HVAC system for special room ventilation (Electrical room) in Uruguay.

Chiller station rebuild in China.

Optimized electric room ventilation for a Finnish customer.