Sustainable Solutions For The Food and Beverage Industries

Processes in food and beverage industries produce CO2 and other harmful pollutants to the atmosphere. Also sidestreams such as sludges are challenges that need professional and sustainable handling without compromising the profitability of the business.

The biggest environmental and economic impact lies in the industries consumption of water and energy. Often the processes involved create large amounts of steam, that traditionally have been vented into the atmosphere. This steam, also containing small amounts of particles and pollutants, is a waste of energy as the water and heat could be much better used within the production process.

Our solutions are suitable for the air conditioning, heating, cooling and drying needs of the food, beverage and distillery industry as well as sludge handling and emission and odor removal of the exhaust air. Optimizing the drying process effectively reduces energy consumption and production costs and minimizes the carbon footprint. We offer several solutions to solve and improve the drying process, for instance: by minimizing the need for energy. Efficient drying solutions also help to exploit the potential of production by-products. For example, commercially valuable components such as starch, protein and fiber can be separated from the by-products of processed roots and vegetables.

Being environmentally friendly has never been so efficient!

Closed circulation:

ZeroEmissions ZeroOdors ZeroFog ZeroIce ZeroDust made with recovered waste energy

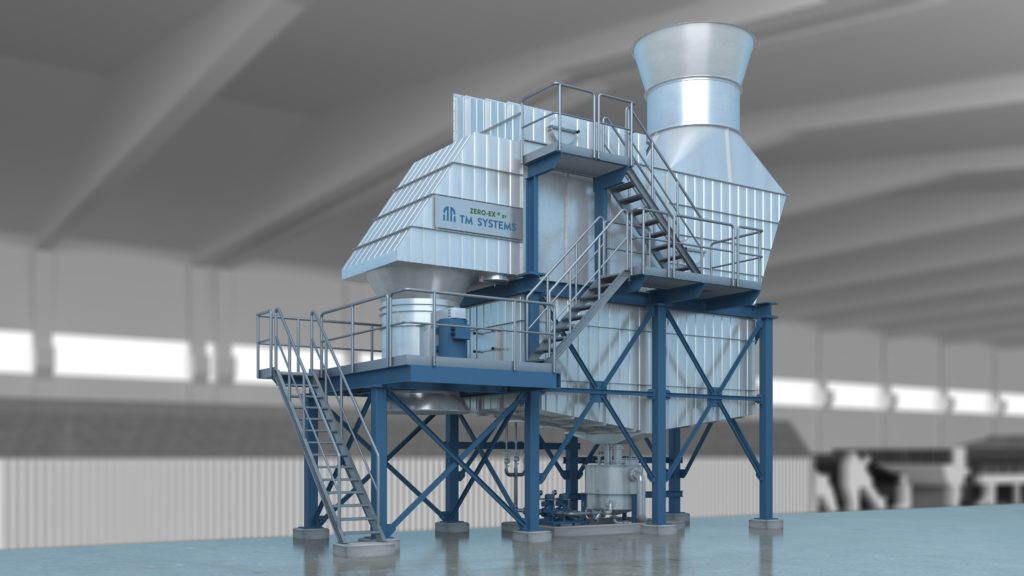

Pollutants, foul odors and wasted energy – typical problems in the food industry. Our proven Zero-Ex® closed circulation technology is specifically designed to combat these problems. In addition to reducing the harmful environmental impact of the pulp industry, Zero-Ex® also improves the efficiency of the processes by recovering wasted heat that would otherwise be exhausted into the atmosphere. Zero Ex® enables a closed loop system in which the energy generated by the process can be recovered with zero waste. By minimizing energy consumption and maximizing the continued use of energy, it is possible to achieve up to 100% energy recovery. Read more: Zero-Ex® – zero emissions to air

Sidestreams and by-products to support bioenergy and circular economy

Side streams and by-products, such as sludge coming out from the food and beverage producing processes and distilleries can be utilized as bedding, fertilizer or as raw material for recycled fibers among other things, to support a circular economy as a substitute for fossil fuels. SuperDryer™ is a breakthrough drying system that revolutionizes the drying process by making it clean, energy efficient and emission-free. It replaces the traditional industrial dryers that are associated with high energy consumption and heavy pollution.

SuperDryer™ is versatile and easily scalable to fit any capacity requirements. The optimal drying conditions and final dryness of the product can be easily adjusted through operating parameters. Together with Zero-Ex® technology it cleans 100% of the exhaust air, eliminates harmful emissions and odors, and recovers 100% of spent energy. SuperDryer™ helps you meet the requirements of the latest environmental regulations and the energy challenges of modern industry. Read more: SuperDryer™ – clean, energy-efficient and CO2 negative drying for sidestreams and sludges

Energy saving

At TM Systems® we are very aware of the energy challenges and the pressure toward environmentally friendly operations in different process industries, therefore, we have put extra effort to further develop energy saving solutions including top-of-the-line heat recovery systems. We deliver solutions that cut energy costs and enable more environmentally friendly production without compromising on production rate.

TM Systems® has developed various heat recovery solutions for food and beverage industries. With our optimized heat recovery solutions you save in energy while still being able to increase your production output. Read more: Energy saving by TM Systems®

Regulatory compliance

Food, beverage and distillery industries face an increasing amount of regulatory sustainability challenges. How to meet the limits without compromising the profitability of the business? Read more: Ensure your regulatory compliance with TM Systems® technology

From fossil fuels to renewables

Is the continuity of your business in danger because of blocked gas supplies? Are you searching for quick alternatives to change from fossil fuels to renewables? TM Systems® has proven technology that rapdly accelerates you transition from natural gas and other fossil fuels to renewable and clean energy, no matter what fuel your process was originally designed to run with. Read more: Shortcut to renewables by TM Systems®

This is TM Systems®

TM Systems® is a leading developer and supplier of industrial air, drying and emission control systems. We are setting standards in paper, board, tissue and pulp industries, mechanical wood, energy and bioenergy, mining, metal, food and recycling industries as well as industrial and urban waste and sidestream processes when turning waste into a source of energy or commodity with business value. We know how to turn an industrial drying process with zero emissions. Read more: TM Systems® in a nutshell

Solutions

for Food and Beverage Industries and Distilleries

Products

for Food and Beverage Industries and Distilleries