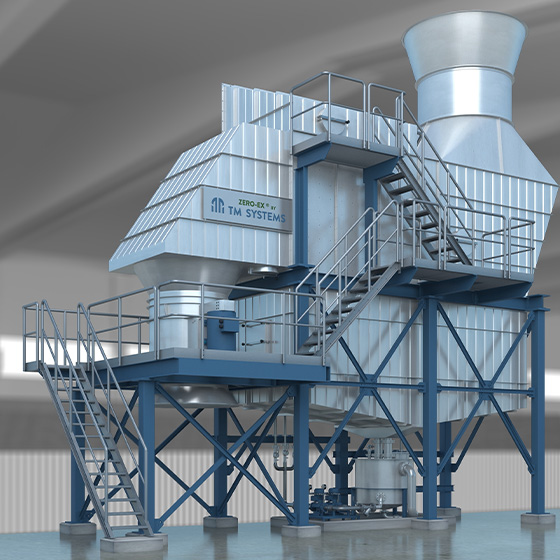

Industrial airborne emissions: ZERO

Capturing emissions and visible vapors moves industries towards sustainable production. Zero-Ex® was developed to solve air pollution challenges while also saving energy and water in pulp and paper industry, mechanical wood industry, food industry, textile industry, etc. Zero-Ex® is an essential step when reducing discharged airborne emissions in polluting industries down to zero.

Zero-Ex® is a self-powered emission capture technology for capturing visible vapor, odor and emissions together with remarkable energy capturing possibilities and environmental benefits.

Zero-Ex® is tailor-made to suit any emissions type, whether it is gases, particle matter, fumes or odor.

Benefits

- Zero-Ex® provides remarkable energy and water savings for pulp and paper mills

- Zero emissions, zero fog, zero noise, zero dust, zero odor

- Zero-Ex® is suitable for any exhaust quantity and can be retrofitted to your existing process

- Closed recirculation of process air

- Payback time is less than two years

How it works

Zero-Ex® technology prevents emission of visible vapors into the atmosphere while simultaneously recovering energy from the drying process exhaust air. Energy is saved by recovering heat and water from the drying process before it is emitted into the atmosphere. Exhaust emissions treatment is tailored to suit the need; from scrubbing to condensing or a combination of several different techniques, Zero-Ex® is tailored to reduce your specific emissions down to zero. The treated and conditioned air after Zero-Ex® can be freely circulated back into the process or exhausted to the atmosphere.

Gaseous emissions+

Process exhaust may contain hazardous and environmentally harmful compounds and their emissions can be strictly regulated. Zero-Ex® can reduce your gaseous emissions through unique and optimized processes. The wide range of treated gaseous compounds includes:

- Sulphureous emissions, such as H2S, SO2, SO3 and thiols (mercaptans)

- Volatile organic compounds (VOC)

- Carbon dioxide emissions (CO2)

- Odors

- Potential other compounds; please contact us for further support for your specific needs

Visible fumes+

Often humid process exhausts produce an abundant fume cloud around the process exhaust outlet. The visible fume can act as a negative association for your production facility. Excel in your emissions targets by removing the visible fumes with our Zero-Ex® fume removal unit, capable of removing any visible vapors without added energy expenditure.

Particle emissions+

Some processes emit particle emissions or dust as a matter of necessity. Zero-Ex® removes both organic and non-organic dusts from the exhaust air, binding the dust in water in a highly efficient way.

Additionally, we can assist in removing the dust directly from the source, minimizing the amount of particles in the exhaust air, before treating the air in the Zero-Ex® dust removal unit.

Heat recovery+

Zero-Ex® combined with our heat recovery equipment can boost your energy efficiency greatly, as both the heat recovery and exhaust air treatment can be accomplished simultaneously. The Zero-Ex® in itself is also able to provide an alternative for heat recovery, if the recovery medium can’t be used in a traditional heat exchanger.

Interested in Zero-Ex® ?

Contact us and our experts will reach out to you.

Solutions

where Zero-Ex® can be used

Industries

where Zero-Ex® can be used