Asia Pulp and Paper (APP) reduces energy consumption at one of the world’s largest pulp and paper mills

The pulp and paper industry is known for being energy-intensive, annually emitting GHGs into the air. Asia Pulp and Paper (APP) was determined to improve production conditions with a new ventilation system.

APP strives to improve their impact on the environment through sustainable innovations. The company set particularly high standards for the ventilation system of one of the world’s largest pulp and paper mills, OKI, built in Palembang Mill, Indonesia.

The humid weather conditions in Indonesia set exceptionally high requirements for controlling ventilation, temperature, and humidity. For example, the air temperature in one laboratory is set to be +23°C, and the air humidity 50% with a tolerance of 1%.

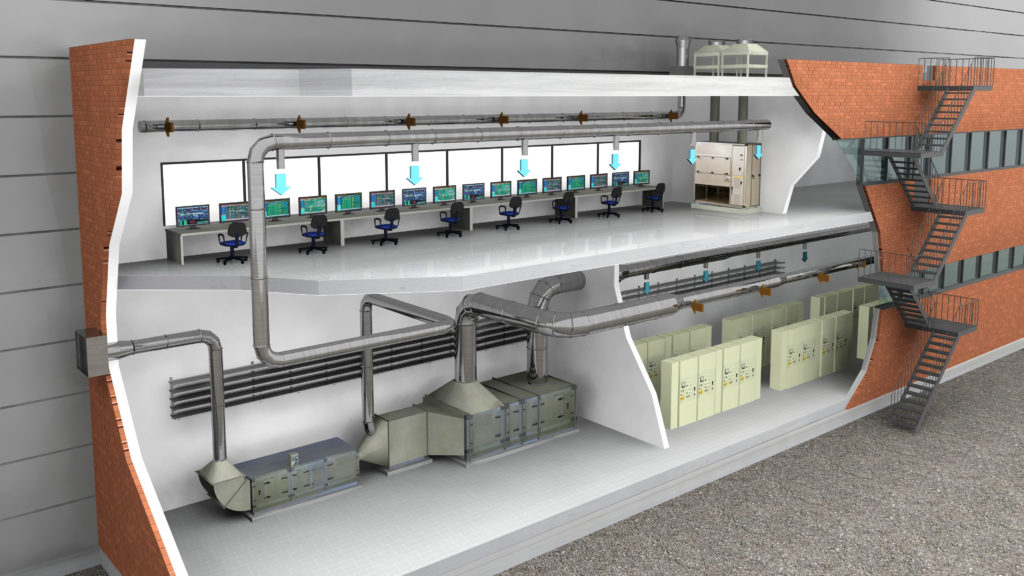

TM Systems® offers HVAC equipment for turbine halls, boiler rooms, control rooms, electrical rooms, laboratory and special rooms.

The client:

Asia Pulp and Paper APP

TM Systems provided:

- HVAC (Heating, ventilation, and air conditioning)

Benefits:

- Better indoor temperature, humidity and atmospheric pressure.

- Ideal working conditions for personnel.

- Innovative solutions with reduced investment costs.

TM Systems product: HVAC (Heating, ventilation, and air conditioning) for auxiliary rooms

A modular HVAC system was built as the project expanded. The main advantage of HVAC is the optimization of the supply of fresh air, that results in minimizing energy usage, as well as reducing any harmful chemicals such as sulphur oxides.

Chilled water system network is used to distribute cool water to the facility as required. Excess air and residual heat from production is used to run the network.

HVAC maintains the indoor temperature, relative humidity, and air pressure within desired tolerances, while chemical filters remove corrosive impurities which are harmful for electrical components, also providing ideal working conditions for personnel.

The controlled air temperature and humidity helps to avoid condensation, as well as deterioration and corrosion of the building, machinery, and electronic devices, thus increasing their lifetime.

TM Systems was able to provide innovative solutions with a highly competitive investment cost.

Long-lasting partnership will continue

Long-term cooperation with TM Systems and demonstrable results from past projects lead yet to another successful delivery. Again, it was confirmed that TM Systems provided APP with the best available technology to meet exceptionally high requirements.

At TM Systems, we are very proud of our remarkable turnkey delivery to this flagship project of Asia Pulp and Paper, and the cooperation will continue from here.

More similar cases

50 years of expertise in the paper and pulp industry, specializing in air and drying solutions for paper machines

50 Years of Expertise in the Paper and Pulp Industry, Specializing in Air and Drying Solutions for Paper Machines For the past 50 years, TM Systems has been a distinguished technology provider i…

Stora Enso, Imatra Mill optimizing energy efficiency and increasing production

Stora Enso, Imatra Mill optimizing energy efficiency and increasing production The operation of buildings accounts for up to 30% of global energy consumption. Stora Enso aimed to take significant step…

Boliden Kevitsa Committed to Employee Well-being and Long-lasting Equipment

Safety First, Sustainability Always: Boliden Kevitsa Committed to Employee Well-being and Long-lasting Equipment Boliden Kevitsa (Finland) is proving that success in the industry goes hand in ha…

Contact us